Building the Titanic

How Steel Is Made for Big Ships

How Steel Is Made for Big Ships

Imagine the Titanic, a giant ship that sailed over 100 years ago. It was one of the biggest, most powerful ships ever made, and it needed to be super strong to carry so many people across the ocean. But what makes a ship strong? The answer is steel!

What is Steel?

Steel is a special kind of metal made from iron, which is one of the most common metals on Earth. People discovered long ago that iron is strong, but if you mix it with a little bit of carbon (which you can think of like adding salt to food), it becomes even stronger. This new mix is called steel, and it’s used to make things that need to be really tough, like buildings, bridges, and, of course, ships!

How Do We Make Steel?

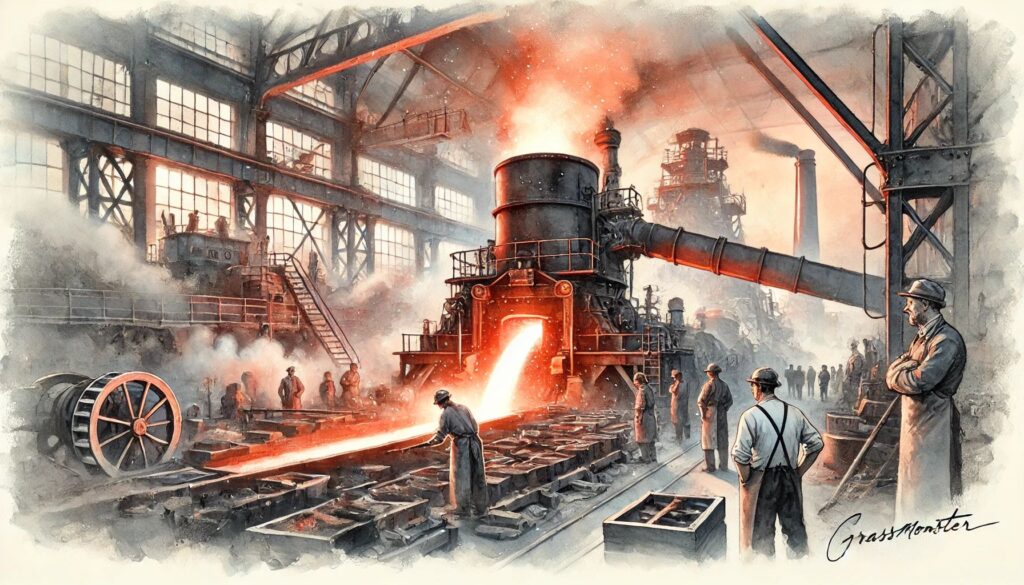

To make steel, workers need something called a blast furnace. Imagine a giant pot that can get as hot as a volcano. Inside this blast furnace, people melt iron and add carbon. They might also add other metals, like manganese or nickel, to make the steel even better for certain things. For ships like the Titanic, they wanted steel that wouldn’t rust easily and could handle rough waves, so they used special ingredients.

Here’s how the steel-making process works step-by-step:

-

Gathering Iron Ore: First, people dig up rocks from the Earth called iron ore. These rocks are full of iron but also have other stuff that needs to be removed.

-

Melting in the Blast Furnace: They put the iron ore into the blast furnace, heating it up until the iron melts. All the unwanted stuff floats to the top and is removed, leaving pure, melted iron.

-

Adding Carbon and Other Elements: Now, they add carbon and maybe other metals to the iron. This mix makes it steel, giving it the strength needed to build something as huge as the Titanic.

-

Pouring the Steel: Once the steel is ready, they pour it into molds to make large blocks or sheets. These blocks will later be shaped and used to build different parts of the ship.

Now take your test